Michael Gove, Secretary of State for Environment, Food and Rural Affairs of the United Kingdom, spoke at The Oxford Farming Conference on January, 3 2019 about technologies shaping the future of agriculture. Secretary Gove believes we are moving into the 4th agricultural revolution, a revolution that will include cell based meat.

Why we care: Secretary Gove argues that due to a high price tag and consumer perception, we are "very far" from introducing eaters to cell based meat. "Very far" resembles a timid uncertainty, but an interesting expectation from a Big 5 government.

CBT Ranking:The U.K. is tied for 6th in our Global Landscape charts.

For ease of access, below is the full transcript of Michael Gove's speech at the Oxford Farming Conference 2019, originally published on gov.uk.

Introduction - History tells us science is the future

One of my favourite Radio Four programmes, second only to Farming Today, is The Long View.

Presented by the superbly talented Guardian columnist Jonathan Freedland, The Long View asks us to consider current events in their historical context, draws parallels between the controversies of our time and the challenges of our past.

Few professions take a longer view than agriculture. Farmers plan, invest and produce for the long-term. While those of us in Westminster live in a world of hourly Twitter storms and daily news cycles where a week is now a very long time in politics, farming requires the patience and foresight to think in harvests and lifecycles, to see beyond the immediate and scan the far horizon.

Of course, the immediate political question which all of us must wrestle with is Brexit - and more particularly how Britain leaves the European Union in less than three months’ time. And I will address that question head on in a moment.

But first I do want to take a deliberately longer view. Because, hugely significant as the changes generated by Brexit will be, it’s important that we consider them in the broader context of the wider forces driving change in farming, food policy and our relationship with the rest of the natural world.

Because the truth is as this conference designed to underline. Our world is entering a fourth agricultural revolution.

The first revolution was the move from hunting and gathering to settlement and cultivation - which made possible the generation of surpluses, the beginning of trade and the establishment of civilisation.

The second agricultural revolution was pioneered here in Britain from the 17th through to the 19th centuries. British farmers and land owners developed more sophisticated crop rotation and new mixed farming methods which more efficiently turned pasture into protein and waste into fertiliser. Alongside the development of new seed drills, selective breeding, large-scale drainage schemes and land reclamation all these changes dramatically increased food production. That helped drive an equally dramatic increase in population numbers, which in turn sustained the industrial revolution.

The third agricultural revolution was even more significant in its scale. In the middle decades of the last century, pioneering work by visionary scientists such as Norman Borlaug, whose granddaughter is with us here today, transformed the scale of food production worldwide. New seed varieties were generated that powerfully improved yields and, alongside improvements in fertiliser manufacture, pest control and other forms of crop protection, they allowed developing nations to overcome scarcity and hunger, laying the groundwork for the global economic growth which has lifted billions out of poverty.

Now, we are on the verge of another revolution in how we produce our food.

That is why I particularly welcome what your chairman, Tom Allen-Stevens, called earlier the ‘brazenly positive’ tone of this conference. ‘We stand on the threshold of new horizons,’ Tom argued. ‘Never before has our industry been offered the World of Opportunity that presents itself here, before us, today.’

He’s right. Accelerating technological advances he mentioned such as the drive towards artificial intelligence, the more sophisticated than ever analysis of big data, drone development, machine learning and robotics will together allow us to dramatically improve productivity on traditionally farmed land not least by reducing the need for labour, minimising the imprint of vehicles on the soil, applying inputs overall more precisely, adjusting cultivation techniques more sensitively and therefore using far fewer natural resources, whether carbon, nitrogen or water, in order to maximise growth.

Data analytics, allied to sensors which monitor the health of livestock, will also allow us to develop the optimal environment for animals, helping us to get their nutrition right, safeguard their welfare and improve both dairy and meat production.

Gene-editing holds out the promise of dramatically accelerating the gains we have secured through selective breeding in the past. The ability to give Mother Nature a helping hand by driving the process of evolution at higher speed should allow us to develop plant varieties and crops which are more resistant to disease and pests and less reliant on chemical protection and chemical fertiliser. They will be higher-yielding and more environmentally sustainable.

Vertical farming, with vegetables grown in temperature, moisture and nutrition-controlled indoor environments can also guarantee improvements in yield while at the same time limiting environmental externalities. And of course, vertical farms not only minimise land use but can of course be located close to the urban population centres they serve.

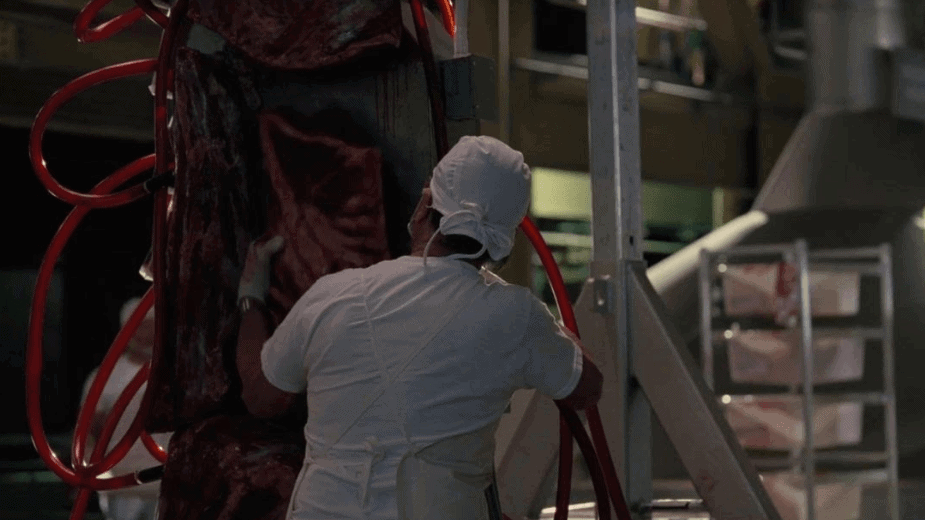

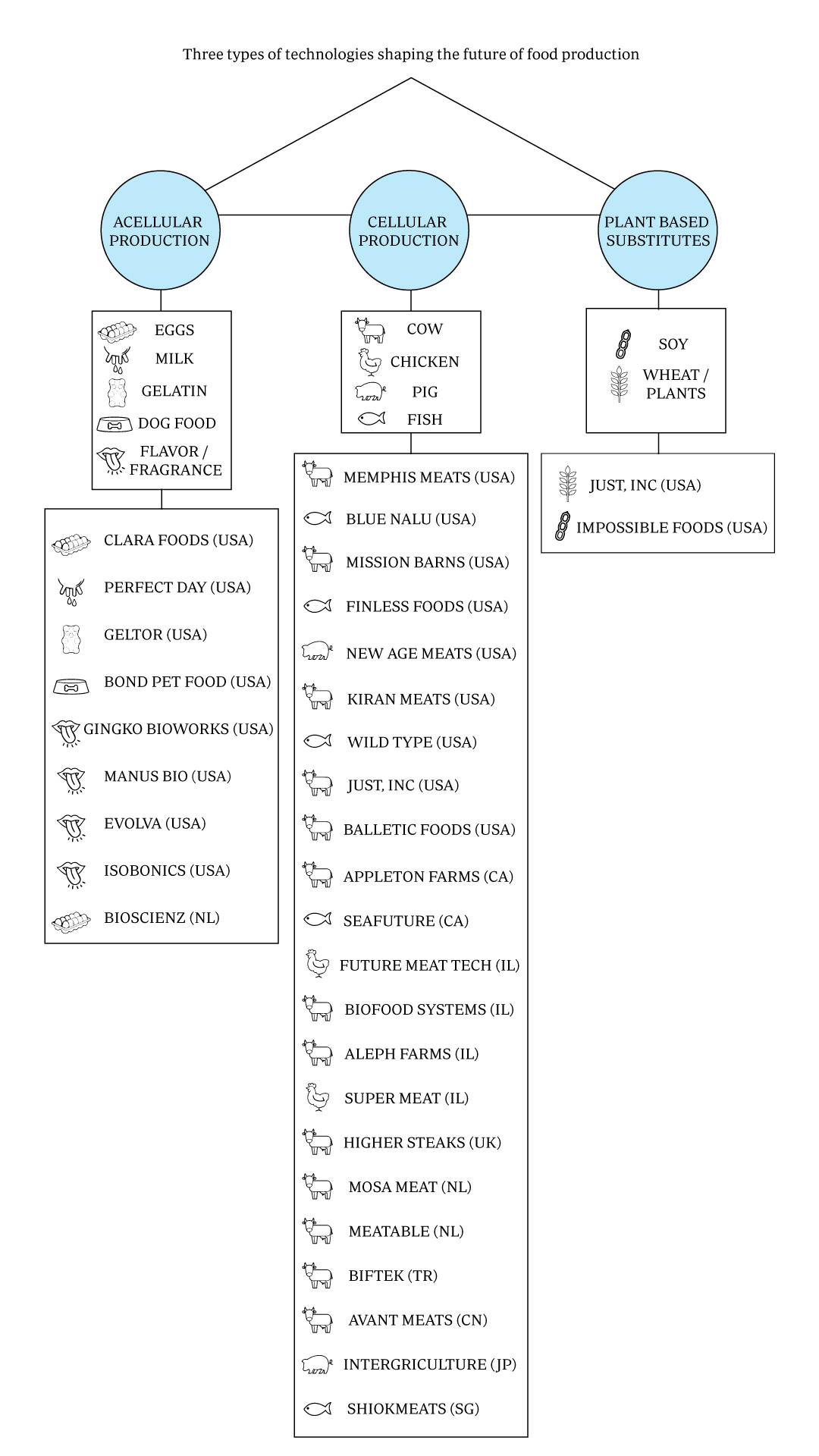

We are also likely to see more and more of our need for protein met by aquaculture and cellular agriculture. Fish farming is an increasingly efficient way of using crops to generate nutritious proteins. And advances in synthetic biology may allow us to create traditional animal products - from gelatine and egg whites to milk and even meat - in labs.

The potential for Britain to lead in this revolution is huge. Which is why Tom Allen-Stevens is right to look to the future with confidence.

Of course, there are challenges. To take advantage of precision technology, AI, robotics and data analytics requires a level of capital investment which is not available to all. There are important ethical, and economic, questions about gene-editing which we need to debate. Vertical farming relies on energy inputs which are currently costly and carbon-intensive. Fish farming of course generates its own environmental externalities. And lab-grown proteins, meanwhile, are very far from everyone’s idea of a mouth-watering treat - and are currently extremely expensive.

But while there are big questions we need to debate about how we handle these new technologies - and where better to debate them than at the Oxford Farming Conference? - we cannot wish away these changes any more than we can ignore having to deal with the impact of climate change, air pollution, soil depletion, global population growth, the stress placed on water resources, the tide of plastic in our oceans, deforestation and biodiversity loss.

Because the background against which this fourth agricultural revolution is occurring - indeed many of the stimuli for it - are the environmental and social factors I’ve just, briefly, listed.

The requirement to use less carbon, to limit the nitrous oxide entering our atmosphere and the nitrates entering our rivers, to improve the organic content and fertility of our soil, to renew, reuse and recycle finite natural resources and yet, at the same time, to also improve resource productivity as the human population grows, all these are the forces driving technological innovation.

Science is thus both making us aware of why agriculture needs to change and also enabling that change to meet our needs.

This fourth agricultural revolution will therefore require us to change the way we work on the land and invest in its future, will force us to reform the role of Government in regulating and supporting farming; will demand new thinking and new talent in food production, and will, inevitably, require tough choices to be made. For some, the adjustment will be undoubtedly challenging.

But no change is not an option.

Reform is vital to modernise the sector and capitalise on technological advances. In 2016/17, more than half of the UK’s farms earned less than £20,000 and a fifth made no profit at all. As John Varley of Clinton Estates observes: ‘These statistics would make most investors that are not looking for tax breaks steer well clear.’

If, however, we embrace the potential of the fourth revolution we can guarantee the future of the United Kingdom as a major global food producer; we can play our part in alleviating poverty and scarcity; we can replenish our store of natural capital, secure investment for the innovations in tackling waste, pollution and emissions which the world will increasingly need - and hand on both a healthier economy and an enriched environment to the next generation. So as the German statesman Otto von Bismarck once put it, ‘If revolution there is to be, far better to undertake it than undergo it.’

So today I hope to outline how Defra sees its role in the midst of this fourth revolution - with respect to all the areas for which the department is responsible - food, the rural economy, and our environment.

Thinking strategically about food

Food first.

Food production has been a success story for Britain. Food and drink is our biggest manufacturing sector, with our food and drink contributing £113 billion to the economy every year. And the consumer has benefited from the enterprise and innovation of our food producers. British citizens have a wider choice of high-quality food than ever before and the cost of food for the consumer has fallen significantly in recent decades.

We have safe, nutritious, affordable food in abundance in this country because of our farmers - their hard work, enterprise and commitment.

But we cannot take this bounty for granted. And nor can we ignore the looming problems that we face.

In a world facing the pressures I listed earlier, how do we provide food security for this country? Do the economics of contemporary food production add up? How do we help those, in this country, and across the globe, who are living in poverty? The diet is central to health, does our approach to food currently maximise human well-being? And critically what do we think is required to make food production in this country truly sustainable?

The fourth agricultural revolution would require us to rethink the future of food in any case, but if coming scientific and technical innovations are to be harnessed wisely, and in harmony with human flourishing, then we need as a country to have a much wider, and more informed, debate about food.

That is why I have asked Defra’s lead non-executive director, the food entrepreneur Henry Dimbleby, to lead on the development of a new Food Strategy. He will be visiting farms and food producers and working with people across the industry to ensure we ask the right questions.

On food security, for example, I think that it is critical that we conceptualise the challenge properly. Our food security currently rests on both healthy domestic food production and of course global trading links.

Healthy domestic production in the future is likely to require not just investment in new technology but are also improving the resilience of the environment on which we depend for future growth. So food security in the future should mean for example, returning soils to robust health, and improving their organic content.

It should also mean keeping pollinator numbers healthy and improving animal welfare and husbandry to minimise health problems and disease risk.

It will probably also require us to build in resilience and flexibility to our agricultural sector so we can deal with changes we cannot anticipate by ensuring we having diversity in the size and type of farm business in this country.

And it also means guarding against those looming changes we can foresee - taking steps to minimise flood risk, adapt to climate change and safeguard biodiversity so we have a rich bank of natural capital on which to draw for the future.

Food security necessarily also involves providing consumers not just with a plentiful and resilient supply of food but with guarantees on provenance and welfare. Which is why the new Livestock Information Programme which Minette Batters has championed and helped to secure this year is so important. It will enable us to reassure domestic consumers on the safety of our produce as well as securing a competitive edge in a world market where quality is increasingly key.

Now of course with respect to future trade, we know that there will always be food, and materials required for food production, which we will have to source from abroad.

But we also know that climate change is going to have an impact on the resilience, and range, of food production in other countries particularly in the global south - so countries like our own will have to play an even more important role in world food production.

And if we are to maintain our own resilience and reputation for quality, that means we must maintain our own high environmental and animal welfare standards, and we must not barter them away in pursuit of a necessarily short-term trade-off.

And that takes me to another one of the key questions about the economics of food production. Affordable food for every citizen is a key goal of public policy. But we should be clear about the real costs of food production.

Beef or soybeans produced to scale on land in other countries that have been cleared of vast hectares of forests may appear cheap but in fact such food is costing the earth. The loss of forest cover imposes environmental costs on all of us, as valuable carbon sinks disappear and a defence against climate change is dismantled. The argument that we can lower the cost of food by importing from countries that have pursued deforestation policies ignores the fact that we all have to pay for the environmental damage in other ways.

There are, of course, other key economic questions the food strategy must address. While consumers have enjoyed the benefits of increased efficiency in British farming why have farmers not reaped anything like the same benefits?

Compared with a generation ago, it is often the case that farmers receive a lower share of the money that we, the public, hand over to supermarkets and other food retailers. That’s in part because of post-farm gate innovation, and supermarkets offering consumers added value – scrubbed potatoes; chickens seasoned and sold in roasting bags – which customers are happy to pay more for, but that innovation has inevitably reduced the percentage of the final price which has gone to the farmer.

So as farmers become even more efficient, and get an even better return per hectare – how can we ensure that we have a profitable farm sector alongside low prices for good food?

Part of the answer is greater transparency. The more information we have – and especially the more information an increasingly discerning public have when they make consumer choices - the better markets work. And if markets aren’t working because some players are operating unfairly or anti-competitively, then government should intervene.

Intervention is also required when it comes to health. The growth in obesity, the acceleration in numbers of patients with Type 2 Diabetes, the spiralling in cases of diet-related heart disease and cancers, all require us to look at the impact of what we eat on how we live, and die.

This challenge, however, requires very careful handling. A crude attempt to label certain foods, meat and dairy, as somehow inherently unhealthy does not do justice to the scale and complexity of the problem and neither does crude calorie labelling.

A proper food strategy must look more widely at the socio-economic factors and trends relating to diet and health problems such as obesity, diabetes and other diet-related illnesses. The fact that these problems disproportionately affect more disadvantaged sectors of society should offend our sense of social justice. That’s why we need to ask searching questions about just where, how and why poor diet occurs – and seek answers.

I want our Food Strategy to be ambitious, to ask big questions, to challenge lazy orthodoxies. To place food security on a sounder footing, enable food producers to plan for the future with confidence, provide a proper understanding of the real economics of the food industry, harness the potential of new technology to improve productivity, make that productivity growth genuinely sustainable - and to improve the nation’s health. I see our Food Strategy as another opportunity for Britain to show a lead in this world of opportunity.

Of course there is already one conspicuous way in which we do lead the world in terms of food. Our universities are home to some of the most respected agriculture, food and environmental science, vet medicine, land management, chemistry, zoology and botany departments in the world. A new generation of farmers, scientists, bio and agri-tech entrepreneurs are already reinforcing Britain’s reputation as a centre of excellence in innovation.

But I want us to go further. There is a huge opportunity for British talent to shape the Fourth Agricultural Revolution. We need to ensure we attract even more talent people into the food and farming industry.

I have been hugely encouraged in that regard by the work of colleagues such as Don Curry, Fiona Kendrick, Peter Kendall and Minette Batters who have been collaborating to think creatively about the skills and talent we will need in the future to maintain leadership in the food production sector.

And we will be saying more about what Government can do to help when recommendations come forward through the Food and Drink Sector Council but I have already been discussing with the Business Secretary Greg Clark and the new Higher Education and Science Minister Chris Skidmore the need for all us collectively to show even greater ambition.

Enhancing the environment for rural businesses

Now of course, food is at the heart of every farming business and farming is the backbone of the rural economy. Our ambition at Defra to lead the world in our thinking about food depends on our ability in the first place to maintain a healthy farming sector and overall a robust rural economy. That in turn requires us to think about the role of Government in supporting all those who work and live in the countryside.

We have already pledged to spend the same level on farm support in cash terms after we leave the European Union right up to the end of this Parliament. That is and often forgotten a greater degree of security over future funding for farming than that enjoyed by any other existing EU nation.

I recognise, however, that farming, because it is a quintessentially long-term business, benefits from as much certainty as possible about the future. And with the scale of change coming that I mentioned earlier, the more assurance we can provide the better.

I cannot, here, entirely pre-empt the outcome of the Government’s Spending Review. But both the Chancellor and the Chief Secretary to the Treasury are committed to using that review to support growth, encourage technological innovation, demonstrate British leadership in areas of business excellence as well as spreading prosperity more equitably across the country. So if we can embrace the changes I’ve been discussing today, we will ensure British agriculture, and the rural economy more widely, will be able to benefit in that Spending Review. Embracing change, supporting reform is the key to unlocking the Treasury’s special box.

But while I cannot pre-empt the outcome of the Spending Review I can continue to demonstrate the case for, and put in place the policies that will underpin, long-term investment.

That is why we have secured a seven-year agricultural transition, beyond the 21-month transition period set out in the EU Withdrawal Agreement, to enable farm businesses to plan ahead.

That is also why we have published proposals to allow for agricultural support payments to be rolled forward into a lump sum which can used now to re-model farm businesses for the future.

And it is also why we have commissioned a review by Lord Bew of Donnegore to look at what factors should be taken into account to ensure an equitable intra-UK allocation of domestic farm support funding.

And, again, in advance of the Spending Review the government has also made a commitment to invest in the extension and improvement of rural broadband coverage. In the Budget the government announced that it would invest a further £200m over the next two years providing full fibre broadband in rural areas. This is in line with the ‘outside-in approach’ set out in last year’s Future Telecoms Infrastructure Review, which committed to connecting remote rural areas so that the UK has a truly nationwide, state-of-the-art, broadband network at last.

Because we all now, the potential of the Fourth Agricultural Revolution will only be fully realised if we ensure the very best levels of digital connectivity across rural Britain and that is why this investment has been prioritised.

All of these investments sit alongside our other commitments to invest in rural communities. In our Agriculture Bill we make provision for payments to improve productivity specifically, to support collaboration and to help rural businesses cope with change. It is critically important that we support efforts to bring farmers together, and also support innovation and collaboration – because that will help ensure that we keep a wide range of different farm businesses resilient in the face of change.

As I mentioned earlier in the context of food security, it is particularly important that we are sensitive to the need of smaller farmers, because I’m acutely aware that for many of them, the changes in how we provide support and the changes in how technology will affect food production raise real challenges. But in many parts of the country it is smaller farmers who preserve, in the words of the Prince of Wales, the culture in agriculture. From the Lake District to Exmoor, from East Sussex to Teesdale, there is alongside our natural environment a delicate human ecology we need to consider, we also need to consider the natural environment as we seek to conserve and enhance.

And in reflecting on the challenges faced by smaller farmers, especially livestock farmers, it is important to be straight about the really significant challenge which would be posed by a no deal Brexit.

Now as I suspect some of you may know, I argued for Britain to leave the European Union and I believe strongly that our departure allows us to rejuvenate our democracy, make power more accountable, escape from the bureaucratic straitjacket of the CAP and develop a more vibrant farming sector with access to technologies the EU is turning its back on.

Leaving the EU also means we can end support for inefficient area-based payments which as we know reward the already wealthy and hold back innovation, and we can move to support genuine productivity enhancement – and also support public goods like clean air or climate change mitigation which stem from the improvement of soil health, the improvement of water quality and or the improvement of pollinator habitats. We can also better support our organic farming, landscape restoration and biodiversity enrichment; as well as improving public access to the countryside.

All of these are real gains which our departure from the EU can bring risk, but these real gains risk being undermined if we leave the EU without a deal.

Of course, a nation as adaptable, resilient and creative as ours can and will flourish over time, even without a deal.

But the turbulence which would be generated by our departure without a deal would be considerable. As I said earlier, it would hit those who are our smaller farmers and smaller food businesses.

I know that some of the predictions about what might happen without a deal have been dismissed as another episode of Project Fear, a re-run of the lurid claims in the 2016 referendum that a vote to leave would trigger an automatic recession.

At the time, I vigorously rejected those projections and indeed was criticised by some for being too dismissive of expert opinion. Well, no recession came and the economic forecasts turned out to be unfounded. But while Project Fear proved to be fiction, when we look at what a no-deal Brexit could involve we do need to be clear about the costs and facts.

A no-deal Brexit means we would face overall tariff rates of around 11% on agricultural products. But some sectors would be much more severely affected.

According to the AHDB’s excellent Horizon report, we export around 15% of our beef production and around a third of lamb. In both cases about 90% of that export trade goes to the EU. Some of that trade is routed through Rotterdam to other markets beyond the EU but most of it goes to European consumers.

It’s a grim but inescapable fact that in the event of a no-deal Brexit, the effective tariffs on beef and sheep meat would be above 40% - in some cases well above that.

While exchange rates might take some of the strain, the costs imposed by new tariffs would undoubtedly exceed any adjustment in the currency markets. And, of course, if the pound does make exports more competitive, it also feeds inflationary pressures at home.

Tariffs are not the only issue. While the EU have pledged to accelerate the process whereby the UK is recognised as a third country and we can continue to export food to their markets freely, all products of animal origin will have to go through border inspection posts and, at the moment, the EU have said 100% of products will face sanitary and phytosanitary checks.

Much of our trade currently reaches European markets through the narrow straits between Dover and Calais. At the moment there are no border inspection posts at Calais. While we do hope the French take steps to build capacity there, that capacity is unlikely by the end of March to be generous.

The EU have also said that hauliers from the UK can carry export goods to EU markets but they cannot make multiple journeys from EU country to EU country and thus the costs of haulage could rise as well.

The combination of significant tariffs when none exist now, friction and checks at the border when none exist now and requirements to re-route or pay more for transport when current arrangements are frictionless, will all add to costs for producers.

As will new labelling requirements, potential delays in the recognition of organic products, potentially reduced labour flows and the need to provide export health certificates for the EU market which are not needed now.

Of course we can, and are at Defra, doing everything to mitigate those costs and are developing plans to help support the industry in a variety of contingencies. But nobody can be blithe or blasé about the real impact on food producers of leaving without a deal.

That is just one of the reasons why I hope my colleagues in Parliament support the Prime Minister’s deal. It isn’t perfect – but we should never make the perfect the enemy of the good. It not only gives us a 21-month transition period in which current access is completely unaffected, it also allows us to maintain continuous tariff-free and quota-free access to EU markets for our exporters after that, allows us to diverge from EU regulation in many areas after the transition; means that we will leave the Common Agricultural Policy and it also ends all mandatory payments to the EU.

If Parliament doesn’t back the Prime Minister’s deal all those gains will be put at risk. If we do secure support for the deal, however, then we can forge ahead with further reforms which can put Britain in a world-leading position, not just in food production but also in the wise stewardship of our natural assets.

The critical business of enhancing the environment

Outside the EU and the CAP we can reward farmers for the goods they generate which are not rewarded in the market.

Our proposed Environmental Land Management contracts will provide farmers and other land managers with a pipeline of income to supplement the money they make from food production, forestry and other business activities. ELMs should be seen as an additional crop, with the Government, rather than a commercial player, entering into a contract with farmers to ensure we increase the provision of environmental services, many of which will also enhance farm productivity.

ELM payments are designed not just to complement existing sources of income but also complement existing initiatives many farmers already pursue.

For example, the adoption of minimum tillage techniques can not only decrease costs and improve productivity but it also reduces run-off and erosion. That is a public good which contributes to improving water quality and for which farmers could be paid.

Similarly, farmers who have chosen to go organic can secure a premium in the market for their produce but their contribution to improving the level of organic matter in our soil also leads to more carbon sequestration and broader environmental resilience. These public goods too could be rewarded.

Uplands livestock farmers, including commoners of course, are responsible for maintaining some of our most iconic landscapes in the condition which not just sustains their farm businesses but also acts as a habitat for precious native species. Improved habitats with more diverse wildlife – which are likely to attract tourist income to less favoured areas – are also a public good we could recognise.

Equally, farmers could be rewarded for enhancing the natural capital of which they are stewards - protecting ancient woodland, bringing woodland under active management or restoring peat bogs. These all generate public goods by adding to our carbon storage, boosting air quality, tackling global warming, and also improving water quality.

And because we recognise that farming is a long-term business we believe these public goods should be paid for through multi-annual contracts.

I recognise that there will be wariness among some about how we propose to administer these contracts because the recent record of delivery with environmental and countryside stewardship payments has been so woeful.

But recent changes at both Natural England and the Rural Payments Agency are beginning to address the problems we face. And we are relentlessly focused on how to streamline the bureaucracy we have inherited under the CAP to ensure farmers can concentrate on their core business of sustainable food production and enhancement of our natural capital.

That is why I commissioned Dame Glenys Stacey to look at the whole landscape of farm regulation and inspection. Her report, which is a brilliant analysis of how to make inspection more proportionate, focused and effective, makes clear that outside the EU and the CAP we can have less onerous inspection, simpler regulation and greater confidence in the maintenance of high standards. Just as I believe we can be world leaders in food production and environmental enhancement so I believe we can, building on Dame Glenys’s work, set the global gold standard in trusted, transparent and efficient regulation of farming.

There is a world of opportunity for British agriculture if we are prepared to embrace the opportunities that our policy reforms and the wider technological revolution can bring.

With an ambitious new Food Strategy, a properly funded 25 Year Environment Plan, rising investment in agritech, world-leading centres of agricultural science, a new generation of entrepreneurs in the food industry, an innovative new system of support for the provision of environmental services and, above all, farmers across the country committed to demonstrating leadership in everything they do - I believe this country, just as it led the Great Agricultural Revolution of the 18th century can be the vanguard nation for this century’s New Agricultural Revolution. And I look forward to the participants in this Oxford Farming Conference leading the way.