Although widely known as lab grown or clean meat, cell based meat is the official term for meat made from the cells of an animal, and grown in a petri dish 🧫

What’s the potential?

The processes to make lab grown meat are still being developed, but potential benefits include higher yields, lower consumer costs, higher quality, and lower environmental impact. For space enthusiasts: consider the potential of feeding a space station or a Mars colony.

Lab Grown

[…]

Although widely known as lab grown or clean meat, cell based meat is the official term for meat made from the cells of an animal, and grown in a petri dish 🧫

What's the potential?

The processes to make lab grown meat are still being developed, but potential benefits include higher yields, lower consumer costs, higher quality, and lower environmental impact. For space enthusiasts: consider the potential of feeding a space station or a Mars colony.

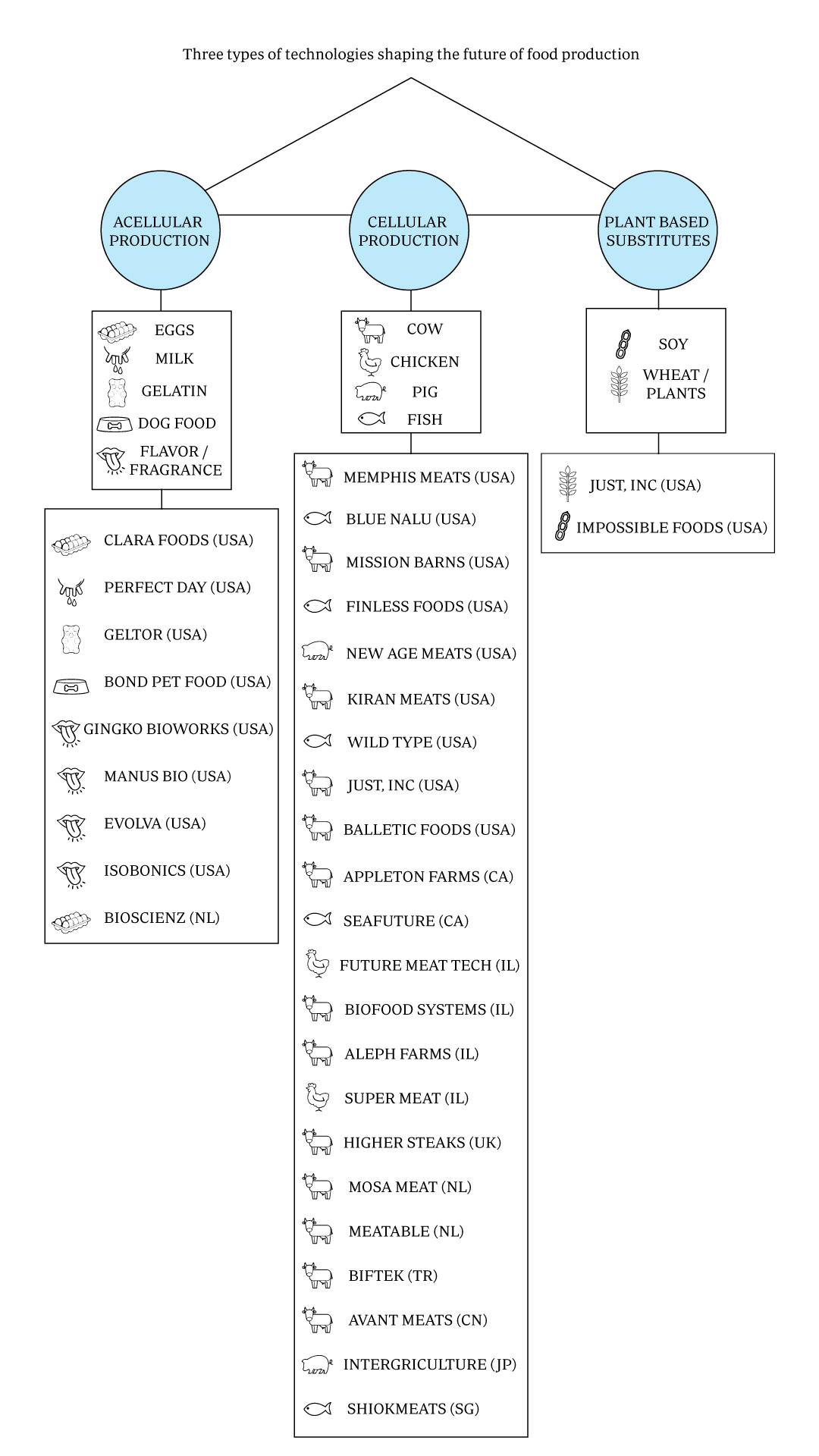

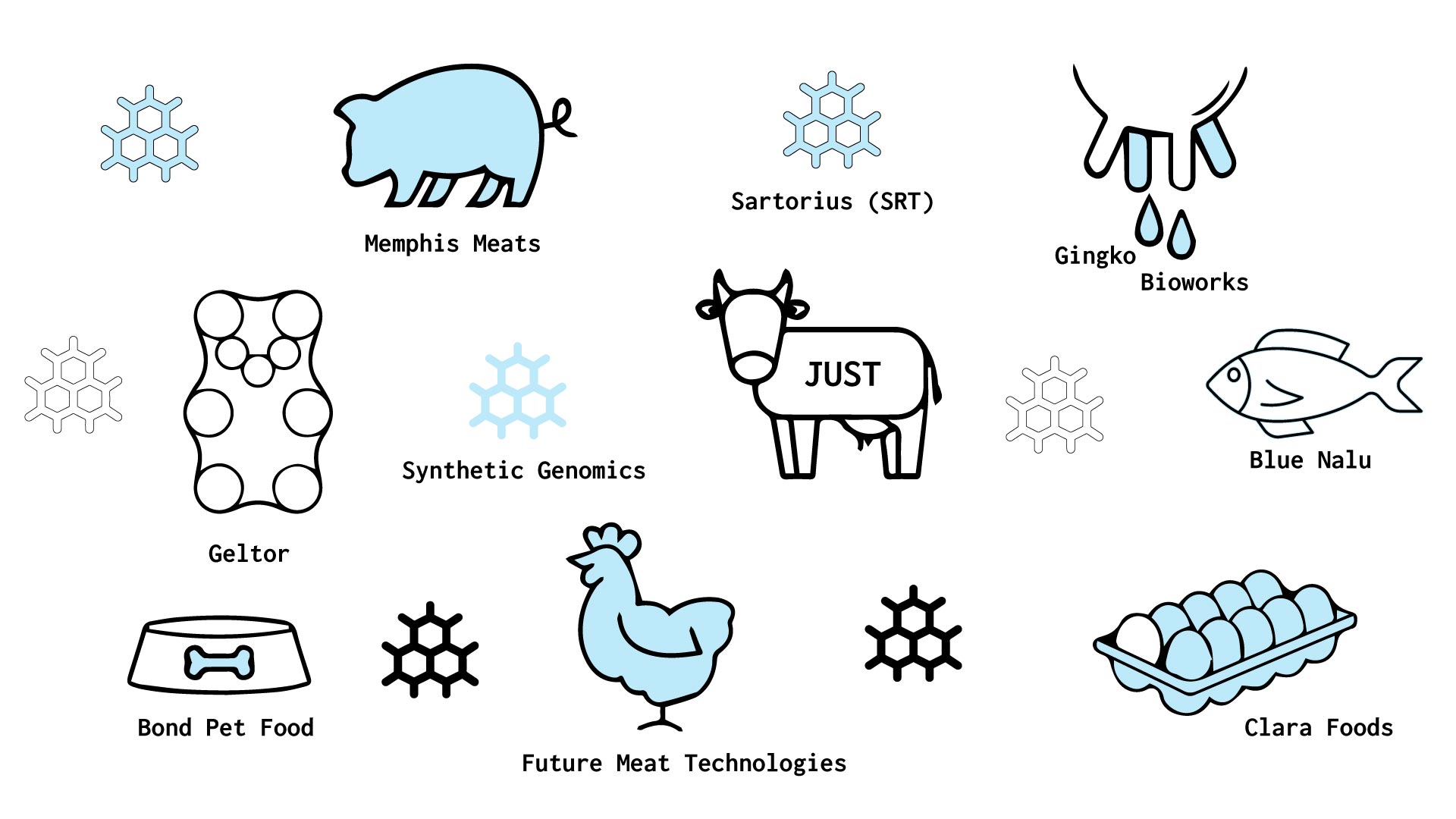

Lab Grown Meat Companies

There are a number of startups globally who are developing cell based meat and foods, with global investments around $1.2 billion. These companies are currently focused on taste, cell culture media, and being able to mass produce at a competitive market price.

Wondering where you can buy it?

Lab grown meat is not available for purchase anywhere in the world. There are some non-meat cell based ingredients available like cell based heme (derived from soybeans), which is found in the plant-based Impossible Burger. Lab grown meat is expected to be available for purchase in 2 to 3 years. However, we are about 6 years away before we see cell based meat in grocery stores, sold at an affordable price.

How is lab grown meat made?

There are currently two processes of making lab grown meat. Read about them and the critical considerations.

Tell us what you think about lab grown meat.