Finnish based company, Solar Foods, completed a Series A financing round raising 15 million Euros ($17,740,200 USD). The round was led by Fazer Group with additional Investors including Agronomics (ANIC), Bridford Investments and CPT Capital. https://cellbased.link/zcx

Background: Solar Foods is using a single cell protein and fermentation technology to produce protein from chemosynthetic bacteria → the bacteria “feed” on CO2 and hydrogen gas. Solar Foods bacteria assimilate CO2 directly as a carbon source through chemosynthesis.

- Commercialized Solein protein

Finnish based company, Solar Foods, completed a Series A financing round raising 15 million Euros ($17,740,200 USD). The round was led by Fazer Group with additional Investors including Agronomics (ANIC), Bridford Investments and CPT Capital. https://cellbased.link/zcx

Background: Solar Foods is using a single cell protein and fermentation technology to produce protein from chemosynthetic bacteria → the bacteria “feed” on CO2 and hydrogen gas. Solar Foods bacteria assimilate CO2 directly as a carbon source through chemosynthesis.

- Commercialized Solein protein would be the first bacterial protein product meant for human consumption.

In other alt protein fermentation news:

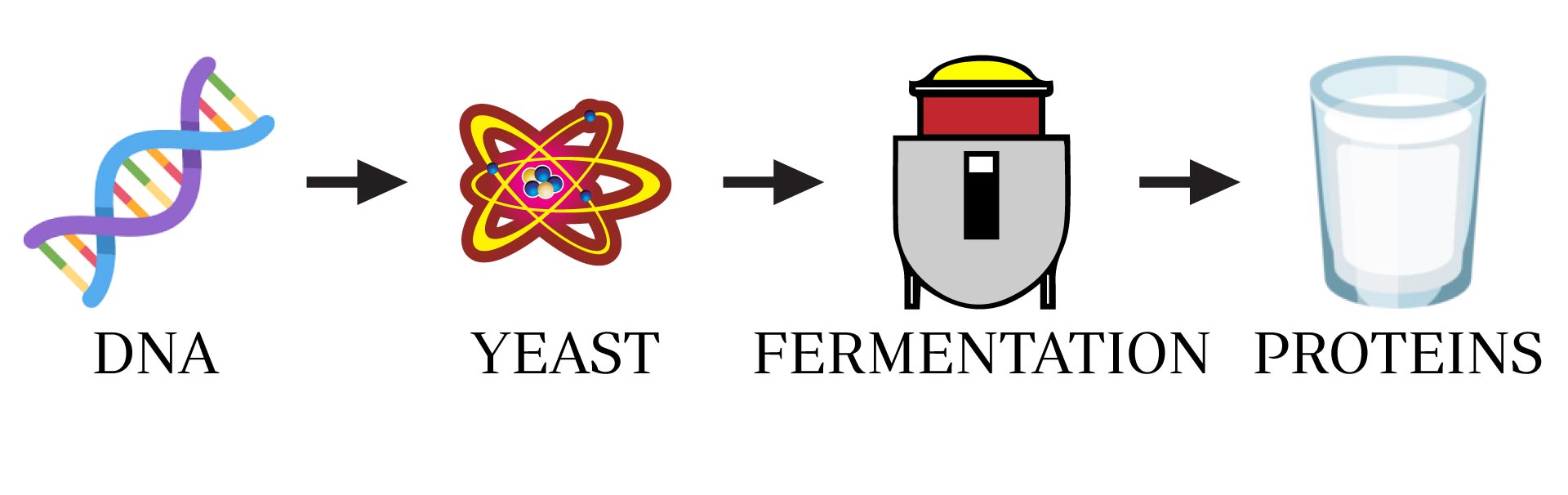

Boulder Colorado based Bond Pet Foods unveiled a prototype of animal free cultured chicken meat protein for pet food applications.

→ Not exactly cell based meat, but Bond Pet Foods used a sample of chicken blood to identify the optimal protein sequence for animal nutrition. The genetic code is used in conjunction with yeast to create a fermentation process to essentially “brew” chicken based proteins for a more sustainable pet food line. https://cellbased.link/51x

- The Milestone was also marked with a bridge investment from Investors including Lever VC and KBW Ventures.

IntegriCulture Japanese Government Grant

Japanese based cell based meat company, IntegriCulture received a $2.2 million government grant from the Japanese Government New Energy and Industrial Technology Development Organization (NEDO). https://cellbased.link/intgov

The grant is intended to be used by IntegriCulture for building a commercial production facility of cell ag products. Based on our understanding of cell based meat, $2.2M is a small step towards building out a commercialized cell ag production facility so this capital may be better suited for pilot scale production. The news comes shortly after IntegriCulture raised $7.4 million Series A in June so it seems the company is slowly but surely moving towards some sort of small scale product launch 2021-2022 (thinking foie gras).